What is Iron Phosphating ?

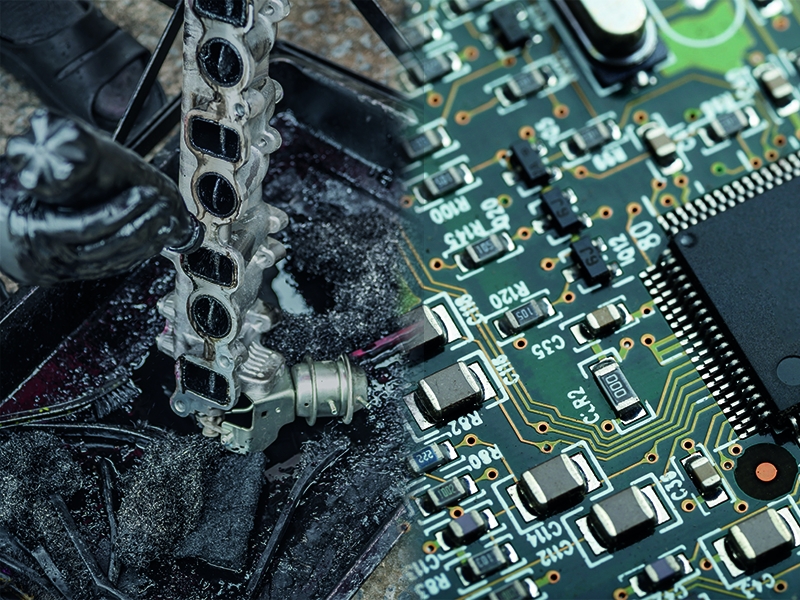

Iron Phosphating: A Process for Metal Surface Protection and Preparation Iron phosphating is a surface treatment method used to prevent corrosion on metal surfaces and prepare them for painting or coating. This process creates a thin layer of iron phosphate (FePO₄) on the surface of iron and steel materials, enhancing their durability and adhesion properties. What is Iron Phosphating? Iron phosphating involves treating metal surfaces with phosphate-based chemicals, primarily phosphoric acid. During the process, a porous and protective phosphate layer forms on the surface. This layer: Improves paint adhesion. Provides resistance to corrosion. How Does the Process Work? Cleaning: Contaminants like oil, dirt, and oxide layers are removed from the metal surface to ensure proper contact with chemicals. Phosphating Bath: The metal is immersed in or sprayed with a solution containing phosphoric acid and additives. This step forms the phosphate layer. Rinsing: Any residual chemicals are washed off the surface. Coating or Painting: The phosphated surface is ready for paint or protective coatings to be applied. Applications Automotive Industry: Commonly used to treat chassis and other metal components before painting. Appliance Manufacturing: Metal parts in washing machines, refrigerators, and other appliances are phosphated. Metal Furniture: Ensures longer-lasting and more durable products. Advantages Corrosion Resistance: Protects metal surfaces from rusting. Excellent Adhesion: Enhances the bond between the metal and the coating material. Cost-Effective and Efficient: Offers a low-cost solution compared to other surface treatments. Environmental Considerations and Precautions Iron phosphating is an environmentally friendly method; however, proper disposal of phosphating baths is essential. Chemicals should be managed in a way that minimizes environmental impact. Conclusion Iron phosphating is a reliable and widely-used method for protecting metal surfaces and improving coating processes. It is an indispensable technique for industries seeking to produce durable and long-lasting products. For more information, consult surface treatment experts or review technical documents related to the process.

Read More